Keep Your Lines Moving

Automate manufacturing workflows to increase production, strengthen supplier relationships, and reduce defects.

Get Started in Hours, Not Quarters

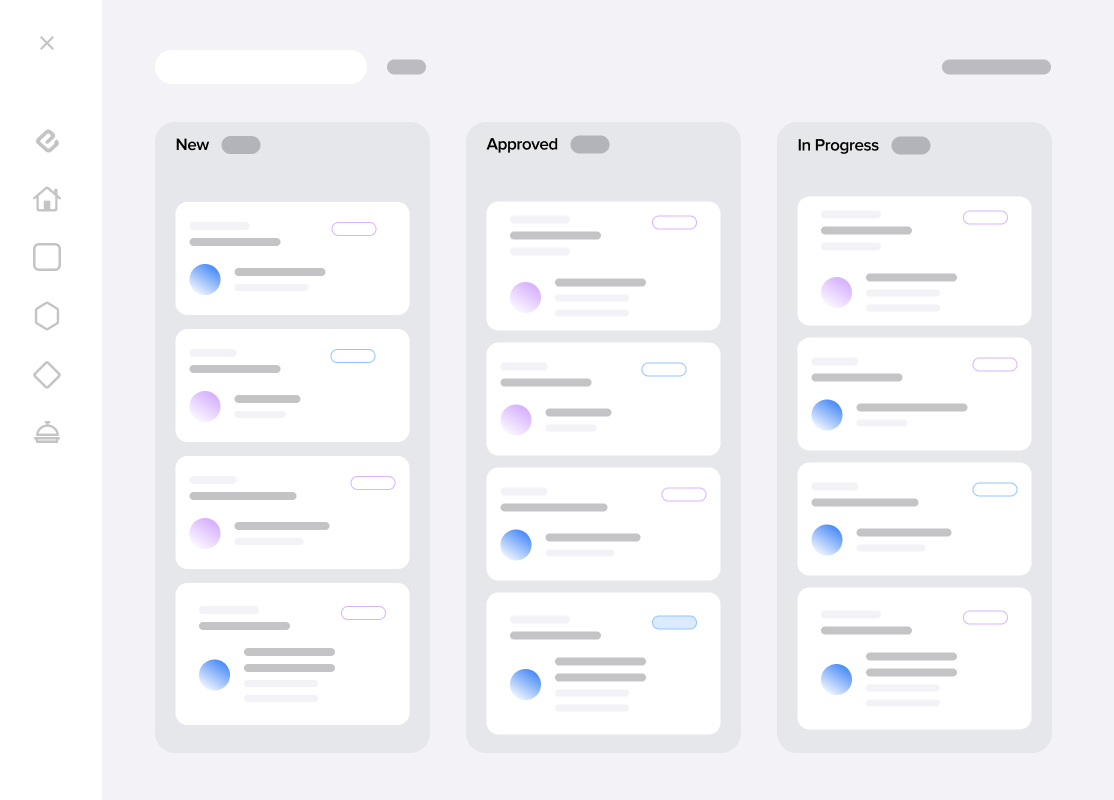

Set up and configure Elementum without engineering resources. Our no-code, zero-ETL platform enables you to:

- Go live in under 24 hours.

- Access 100s of pre-built workflows

- Realize 100% payback in 30 days or less

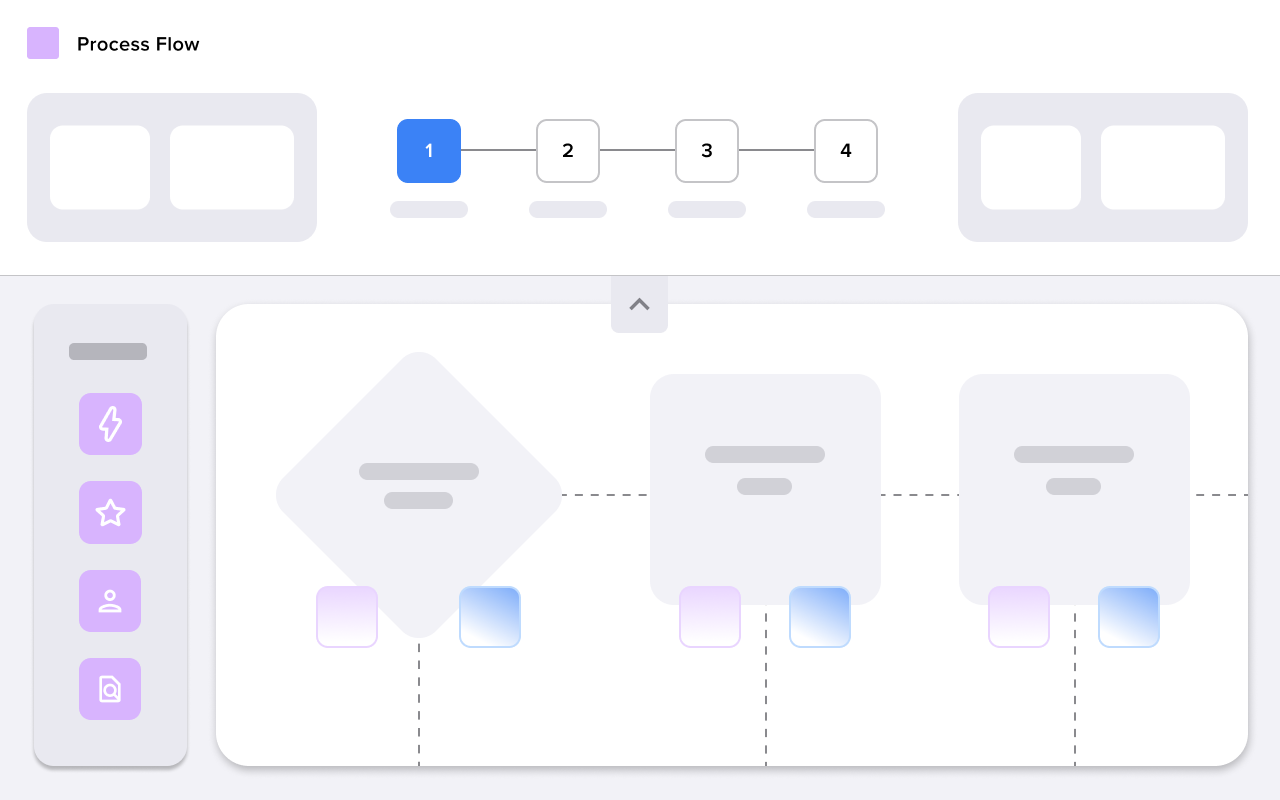

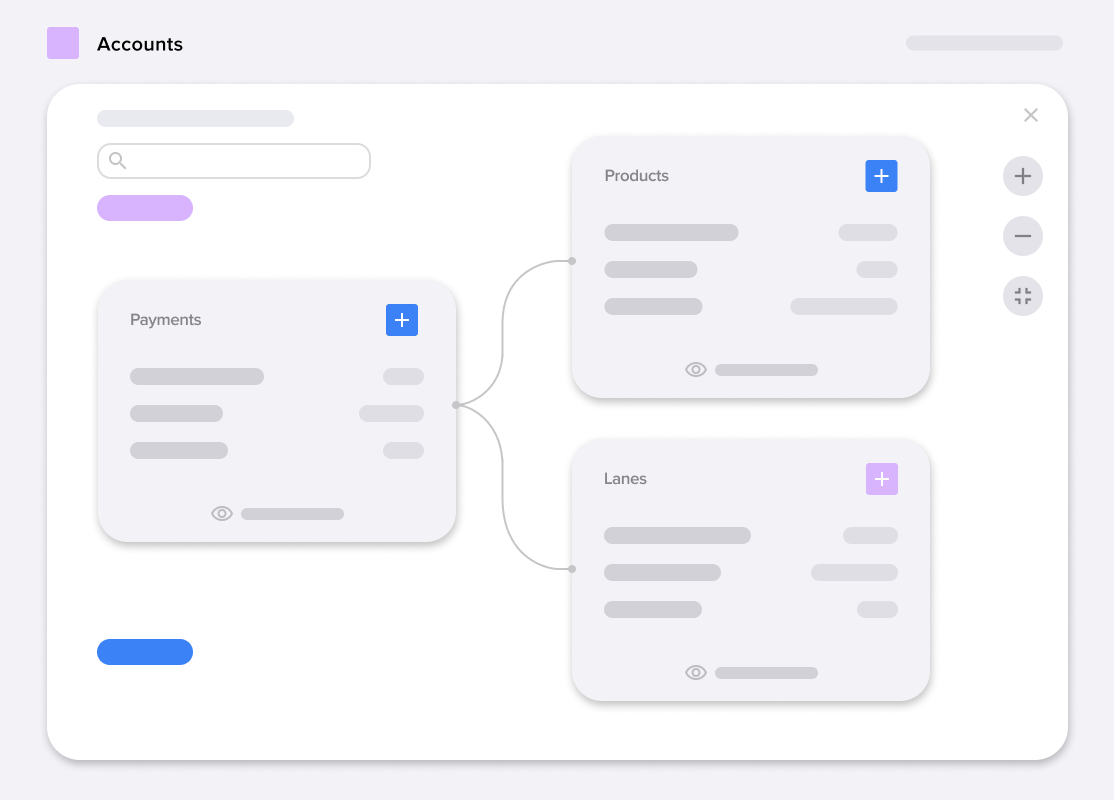

Make AI Work for You, Not the Other Way Around

Leverage AI, ML, and LLMs without data science expertise or complex infrastructure. With Elementum, you can:

- Use built-in models, third-party models, or bring your own

- Turn data into intelligent action instantly

- Use pre-trained LLMs to run your workflows

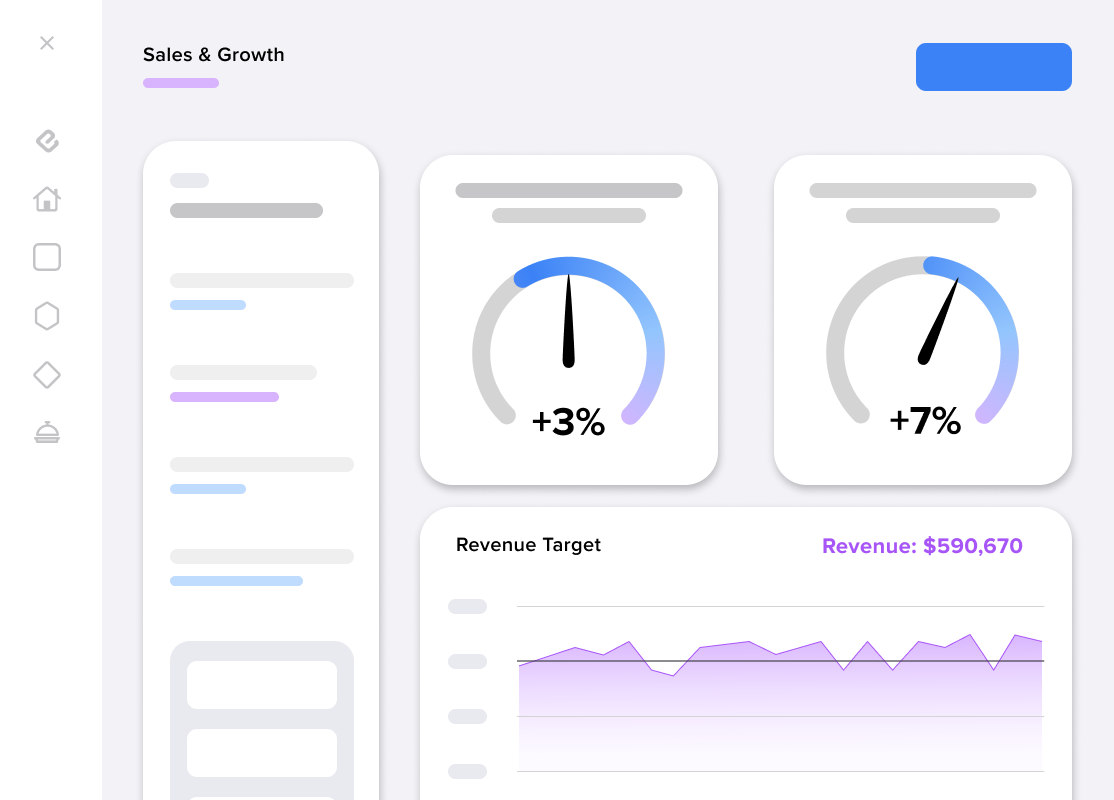

AI Driven Workflows for Manufacturing

Instantly automate any business processes, from the stockroom to the showroom.

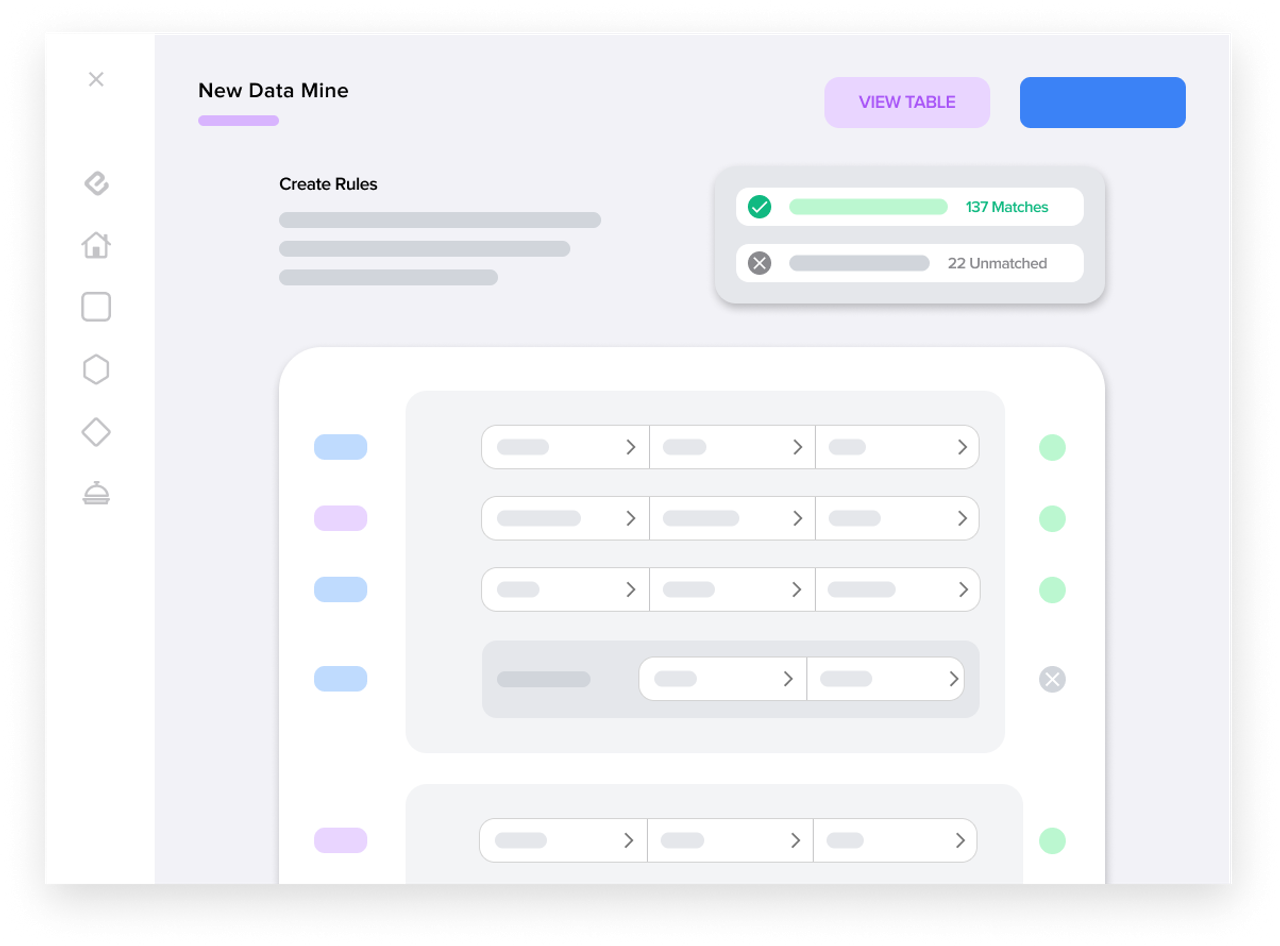

Detect Performance Anomalies

Detect performance anomalies to prevent equipment failures before they happen and improve Overall Equipment Effectiveness (OEE).

Automate Quality Control

Automate quality control and exception management across the production line to proactively identify and resolve issues.

Ensure Regulatory Compliance

Ensure regulatory compliance and accelerate new product development

Optimize Asset Management

Optimize asset management and improve safety and compliance

Streamline Formula Management

Automate batch processing, track inventory, and streamline formula management

Automate Any Manufacturing Process with Your Data

Elementum helps teams like yours do more with their data. Here are a few examples:

Supply Chain Management

Automatically balance inventory, minimize waste, and resolve late shipments to ensure products are available at the right time, place, quantity, and cost.

Production Planning

Forecast demand, optimize production schedules, and allocate resources effectively.

Quality Control

Automate quality inspections, detect defects, and track compliance to maintain high product standards and reduce rework.

Predictive Maintenance

Monitor equipment performance, predict potential failures, and schedule maintenance proactively to minimize downtime and extend asset life.

Improve Supplier Relationships

Automate communication, performance tracking, and issue resolution with suppliers to foster strong relationships and ensure timely, high-quality deliveries.

Accelerate New Product Releases

Streamline the end-to-end process from design to production, automating tasks such as BOM management, change orders, and version control.